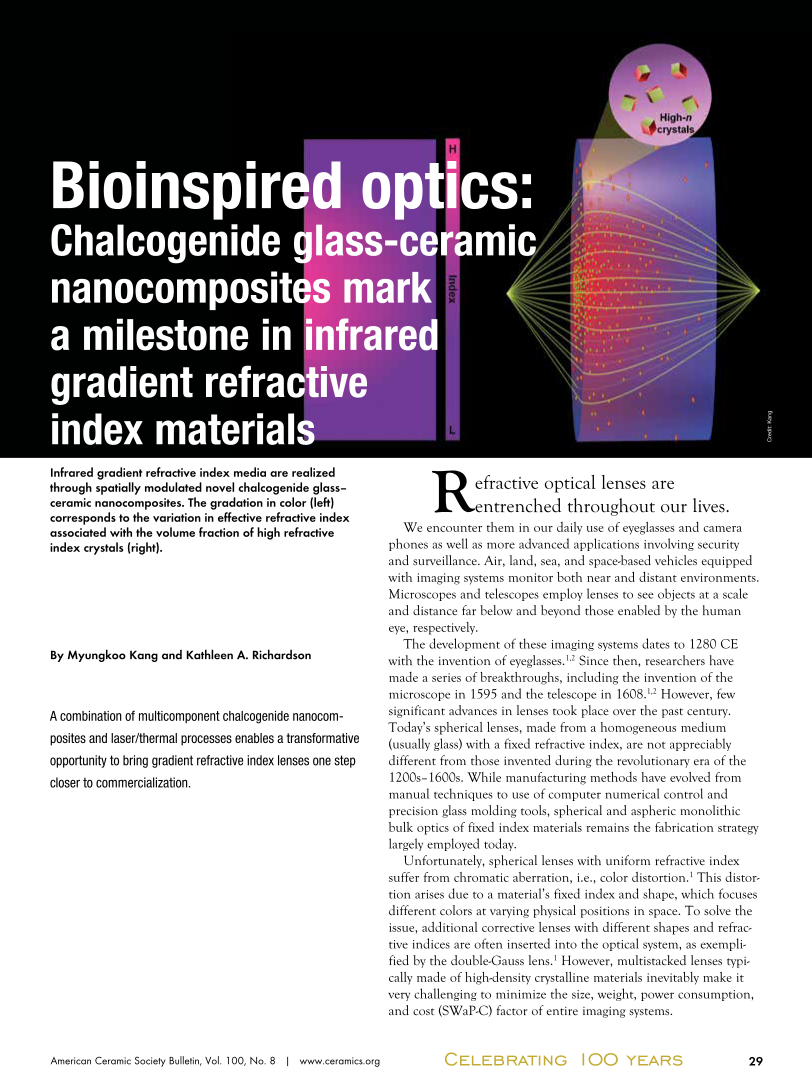

29 American Ceramic Society Bulletin, Vol. 100, No. 8 | www.ceramics.org Celebrating 100 years Bioinspired optics: Chalcogenide glass-ceramic nanocomposites mark a milestone in infrared gradient refractive index materials Infrared gradient refractive index media are realized through spatially modulated novel chalcogenide glass– ceramic nanocomposites. The gradation in color (left) corresponds to the variation in effective refractive index associated with the volume fraction of high refractive index crystals (right). R efractive optical lenses are entrenched throughout our lives. We encounter them in our daily use of eyeglasses and camera phones as well as more advanced applications involving security and surveillance. Air, land, sea, and space-based vehicles equipped with imaging systems monitor both near and distant environments. Microscopes and telescopes employ lenses to see objects at a scale and distance far below and beyond those enabled by the human eye, respectively. The development of these imaging systems dates to 1280 CE with the invention of eyeglasses.1,2 Since then, researchers have made a series of breakthroughs, including the invention of the microscope in 1595 and the telescope in 1608.1,2 However, few significant advances in lenses took place over the past century. Today’s spherical lenses, made from a homogeneous medium (usually glass) with a fixed refractive index, are not appreciably different from those invented during the revolutionary era of the 1200s–1600s. While manufacturing methods have evolved from manual techniques to use of computer numerical control and precision glass molding tools, spherical and aspheric monolithic bulk optics of fixed index materials remains the fabrication strategy largely employed today. Unfortunately, spherical lenses with uniform refractive index suffer from chromatic aberration, i.e., color distortion.1 This distor- tion arises due to a material’s fixed index and shape, which focuses different colors at varying physical positions in space. To solve the issue, additional corrective lenses with different shapes and refrac- tive indices are often inserted into the optical system, as exempli- fied by the double-Gauss lens.1 However, multistacked lenses typi- cally made of high-density crystalline materials inevitably make it very challenging to minimize the size, weight, power consumption, and cost (SWaP-C) factor of entire imaging systems. By Myungkoo Kang and Kathleen A. Richardson A combination of multicomponent chalcogenide nanocom- posites and laser/thermal processes enables a transformative opportunity to bring gradient refractive index lenses one step closer to commercialization. Credit: Kang

(c) 2024 American Ceramic Society. All Rights reserved.