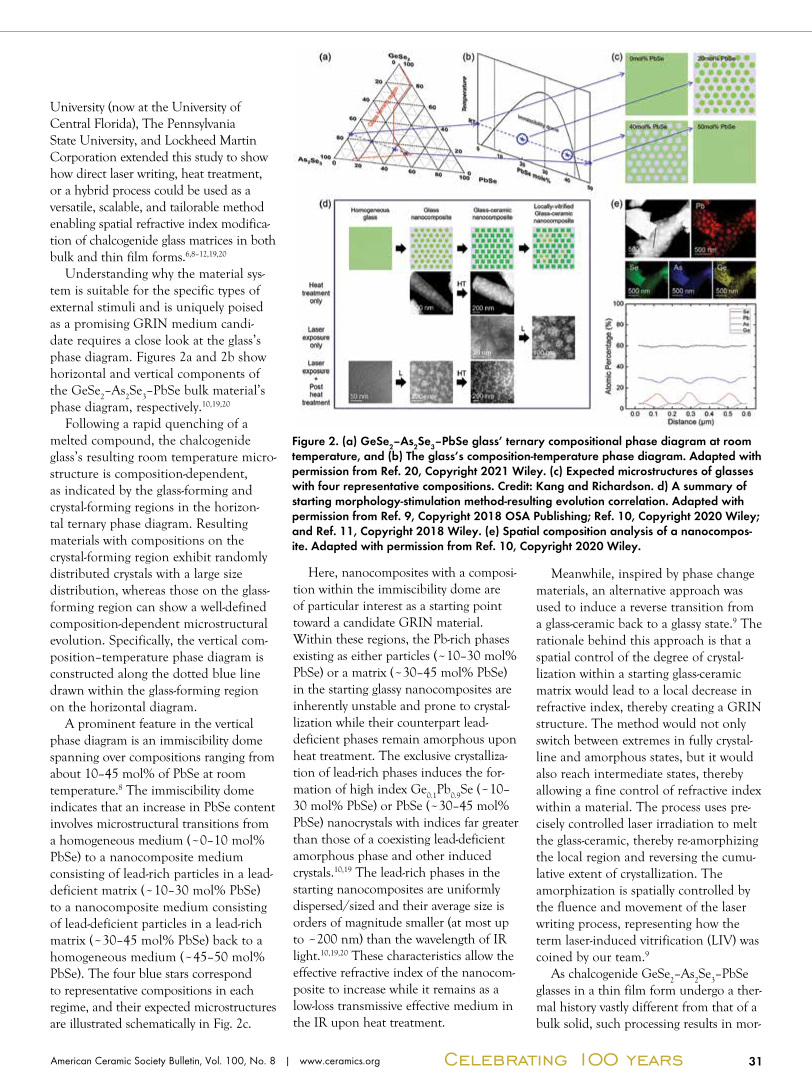

31 American Ceramic Society Bulletin, Vol. 100, No. 8 | www.ceramics.org Celebrating 100 years University (now at the University of Central Florida), The Pennsylvania State University, and Lockheed Martin Corporation extended this study to show how direct laser writing, heat treatment, or a hybrid process could be used as a versatile, scalable, and tailorable method enabling spatial refractive index modifica- tion of chalcogenide glass matrices in both bulk and thin film forms.6,8–12,19,20 Understanding why the material sys- tem is suitable for the specific types of external stimuli and is uniquely poised as a promising GRIN medium candi- date requires a close look at the glass’s phase diagram. Figures 2a and 2b show horizontal and vertical components of the GeSe 2 –As 2 Se 3 –PbSe bulk material’s phase diagram, respectively.10,19,20 Following a rapid quenching of a melted compound, the chalcogenide glass’s resulting room temperature micro- structure is composition-dependent, as indicated by the glass-forming and crystal-forming regions in the horizon- tal ternary phase diagram. Resulting materials with compositions on the crystal-forming region exhibit randomly distributed crystals with a large size distribution, whereas those on the glass- forming region can show a well-defined composition-dependent microstructural evolution. Specifically, the vertical com- position–temperature phase diagram is constructed along the dotted blue line drawn within the glass-forming region on the horizontal diagram. A prominent feature in the vertical phase diagram is an immiscibility dome spanning over compositions ranging from about 10–45 mol% of PbSe at room temperature.8 The immiscibility dome indicates that an increase in PbSe content involves microstructural transitions from a homogeneous medium ( ~ 0–10 mol% PbSe) to a nanocomposite medium consisting of lead-rich particles in a lead- deficient matrix ( ~ 10–30 mol% PbSe) to a nanocomposite medium consisting of lead-deficient particles in a lead-rich matrix ( ~ 30–45 mol% PbSe) back to a homogeneous medium ( ~ 45–50 mol% PbSe). The four blue stars correspond to representative compositions in each regime, and their expected microstructures are illustrated schematically in Fig. 2c. Here, nanocomposites with a composi- tion within the immiscibility dome are of particular interest as a starting point toward a candidate GRIN material. Within these regions, the Pb-rich phases existing as either particles ( ~ 10–30 mol% PbSe) or a matrix ( ~ 30–45 mol% PbSe) in the starting glassy nanocomposites are inherently unstable and prone to crystal- lization while their counterpart lead- deficient phases remain amorphous upon heat treatment. The exclusive crystalliza- tion of lead-rich phases induces the for- mation of high index Ge 0.1 Pb 0.9 Se ( ~ 10– 30 mol% PbSe) or PbSe ( ~ 30–45 mol% PbSe) nanocrystals with indices far greater than those of a coexisting lead-deficient amorphous phase and other induced crystals.10,19 The lead-rich phases in the starting nanocomposites are uniformly dispersed/sized and their average size is orders of magnitude smaller (at most up to ~ 200 nm) than the wavelength of IR light.10,19,20 These characteristics allow the effective refractive index of the nanocom- posite to increase while it remains as a low-loss transmissive effective medium in the IR upon heat treatment. Meanwhile, inspired by phase change materials, an alternative approach was used to induce a reverse transition from a glass-ceramic back to a glassy state.9 The rationale behind this approach is that a spatial control of the degree of crystal- lization within a starting glass-ceramic matrix would lead to a local decrease in refractive index, thereby creating a GRIN structure. The method would not only switch between extremes in fully crystal- line and amorphous states, but it would also reach intermediate states, thereby allowing a fine control of refractive index within a material. The process uses pre- cisely controlled laser irradiation to melt the glass-ceramic, thereby re-amorphizing the local region and reversing the cumu- lative extent of crystallization. The amorphization is spatially controlled by the fluence and movement of the laser writing process, representing how the term laser-induced vitrification (LIV) was coined by our team.9 As chalcogenide GeSe 2 –As 2 Se 3 –PbSe glasses in a thin film form undergo a ther- mal history vastly different from that of a bulk solid, such processing results in mor- Figure 2. (a) GeSe 2 –As 2 Se 3 –PbSe glass’ ternary compositional phase diagram at room temperature, and (b) The glass’s composition-temperature phase diagram. Adapted with permission from Ref. 20, Copyright 2021 Wiley. (c) Expected microstructures of glasses with four representative compositions. Credit: Kang and Richardson. d) A summary of starting morphology-stimulation method-resulting evolution correlation. Adapted with permission from Ref. 9, Copyright 2018 OSA Publishing Ref. 10, Copyright 2020 Wiley and Ref. 11, Copyright 2018 Wiley. (e) Spatial composition analysis of a nanocompos- ite. Adapted with permission from Ref. 10, Copyright 2020 Wiley.

(c) 2024 American Ceramic Society. All Rights reserved.