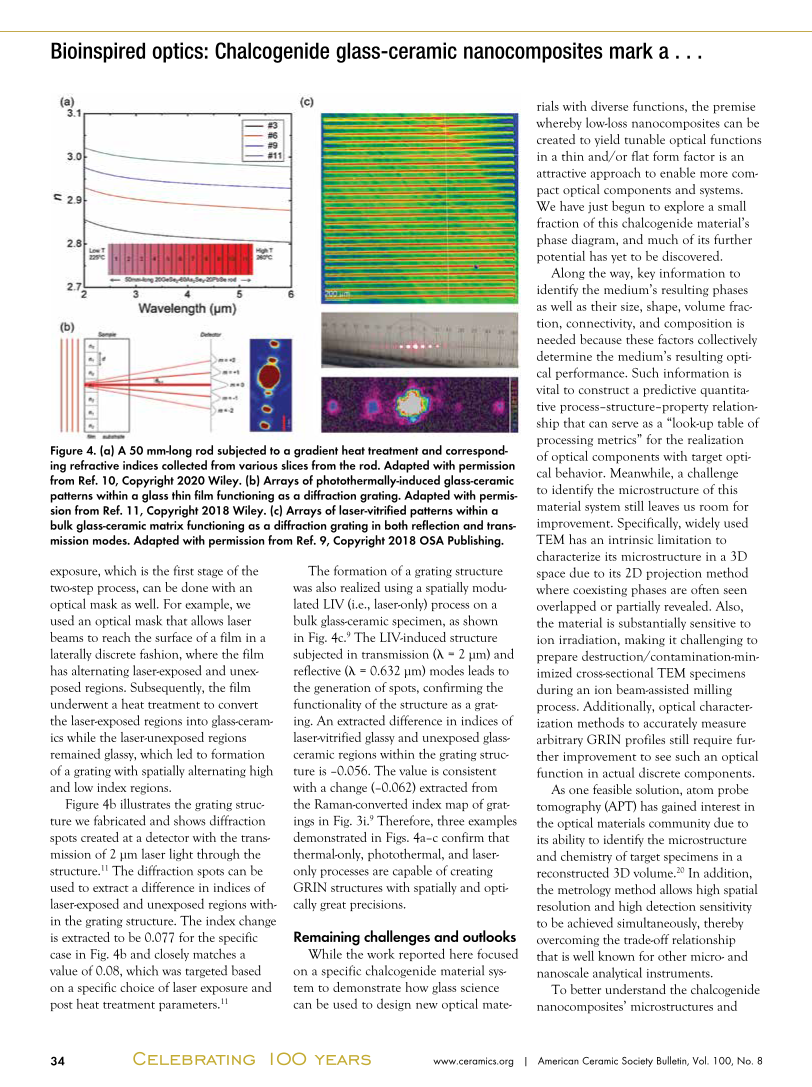

www.ceramics.org | American Ceramic Society Bulletin, Vol. 100, No. 8 34 Bioinspired optics: Chalcogenide glass-ceramic nanocomposites mark a . . . Celebrating 100 years exposure, which is the first stage of the two-step process, can be done with an optical mask as well. For example, we used an optical mask that allows laser beams to reach the surface of a film in a laterally discrete fashion, where the film has alternating laser-exposed and unex- posed regions. Subsequently, the film underwent a heat treatment to convert the laser-exposed regions into glass-ceram- ics while the laser-unexposed regions remained glassy, which led to formation of a grating with spatially alternating high and low index regions. Figure 4b illustrates the grating struc- ture we fabricated and shows diffraction spots created at a detector with the trans- mission of 2 µm laser light through the structure.11 The diffraction spots can be used to extract a difference in indices of laser-exposed and unexposed regions with- in the grating structure. The index change is extracted to be 0.077 for the specific case in Fig. 4b and closely matches a value of 0.08, which was targeted based on a specific choice of laser exposure and post heat treatment parameters.11 The formation of a grating structure was also realized using a spatially modu- lated LIV (i.e., laser-only) process on a bulk glass-ceramic specimen, as shown in Fig. 4c.9 The LIV-induced structure subjected in transmission ( = 2 μm) and reflective ( = 0.632 μm) modes leads to the generation of spots, confirming the functionality of the structure as a grat- ing. An extracted difference in indices of laser-vitrified glassy and unexposed glass- ceramic regions within the grating struc- ture is –0.056. The value is consistent with a change (–0.062) extracted from the Raman-converted index map of grat- ings in Fig. 3i.9 Therefore, three examples demonstrated in Figs. 4a–c confirm that thermal-only, photothermal, and laser- only processes are capable of creating GRIN structures with spatially and opti- cally great precisions. Remaining challenges and outlooks While the work reported here focused on a specific chalcogenide material sys- tem to demonstrate how glass science can be used to design new optical mate- rials with diverse functions, the premise whereby low-loss nanocomposites can be created to yield tunable optical functions in a thin and/or flat form factor is an attractive approach to enable more com- pact optical components and systems. We have just begun to explore a small fraction of this chalcogenide material’s phase diagram, and much of its further potential has yet to be discovered. Along the way, key information to identify the medium’s resulting phases as well as their size, shape, volume frac- tion, connectivity, and composition is needed because these factors collectively determine the medium’s resulting opti- cal performance. Such information is vital to construct a predictive quantita- tive process–structure–property relation- ship that can serve as a “look-up table of processing metrics” for the realization of optical components with target opti- cal behavior. Meanwhile, a challenge to identify the microstructure of this material system still leaves us room for improvement. Specifically, widely used TEM has an intrinsic limitation to characterize its microstructure in a 3D space due to its 2D projection method where coexisting phases are often seen overlapped or partially revealed. Also, the material is substantially sensitive to ion irradiation, making it challenging to prepare destruction/contamination-min- imized cross-sectional TEM specimens during an ion beam-assisted milling process. Additionally, optical character- ization methods to accurately measure arbitrary GRIN profiles still require fur- ther improvement to see such an optical function in actual discrete components. As one feasible solution, atom probe tomography (APT) has gained interest in the optical materials community due to its ability to identify the microstructure and chemistry of target specimens in a reconstructed 3D volume.20 In addition, the metrology method allows high spatial resolution and high detection sensitivity to be achieved simultaneously, thereby overcoming the trade-off relationship that is well known for other micro- and nanoscale analytical instruments. To better understand the chalcogenide nanocomposites’ microstructures and Figure 4. (a) A 50 mm-long rod subjected to a gradient heat treatment and correspond- ing refractive indices collected from various slices from the rod. Adapted with permission from Ref. 10, Copyright 2020 Wiley. (b) Arrays of photothermally-induced glass-ceramic patterns within a glass thin film functioning as a diffraction grating. Adapted with permis- sion from Ref. 11, Copyright 2018 Wiley. (c) Arrays of laser-vitrified patterns within a bulk glass-ceramic matrix functioning as a diffraction grating in both reflection and trans- mission modes. Adapted with permission from Ref. 9, Copyright 2018 OSA Publishing.

(c) 2024 American Ceramic Society. All Rights reserved.